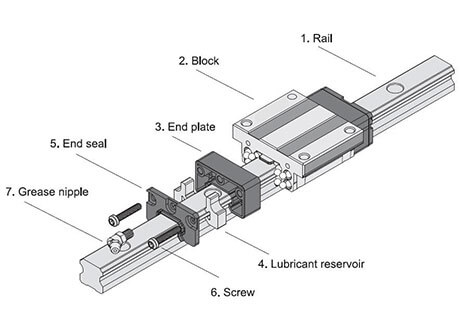

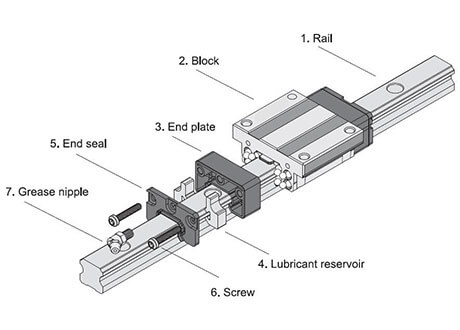

Self-Lubricating Linear Guide (Flanged,Extended length)

Product Introduction

Characteristics:

- BR lubrication reservoir kit (patent).

- Equivalent load capacities in four directions.

- Smooth running due to new ball-circulation.

- High rigidity-4-row angular contact.

- International standard dimension.

- High accuracy and low friction.

- High speed, low noise.

- Integral all-round sealing.

- Interchangeability.

- Green production.

- Long operating life with long-term automatic maintenance of lubricating oil film protection on the rail.

Maintenance and Usage:

- Linear Guide products will be rust-proofed before shipment. Therefore, before using this product, please clean the anti- rust oil first. And then please fill in with lubricant oil immediately.

- Linear Guide was equipped with self-lubricating system (may be different all depends on the model No) which greatly saves the lubricants cost as well as reducing the maintenance frequency. Please check the operating conditions regularly. If there is no oil film on the surface of the rails, please fill in the lubricants immediately.

- Do not disassemble the block by yourself, please avoid foreign matter enter the block, which may affect the accuracy and shorten the service life.

- Do not use at the environment higher than 80 degrees Celsius, it may damage the seals of the product and shorten the service life.

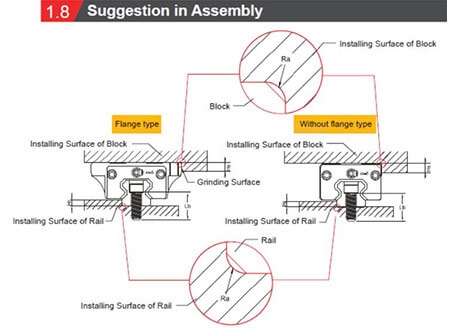

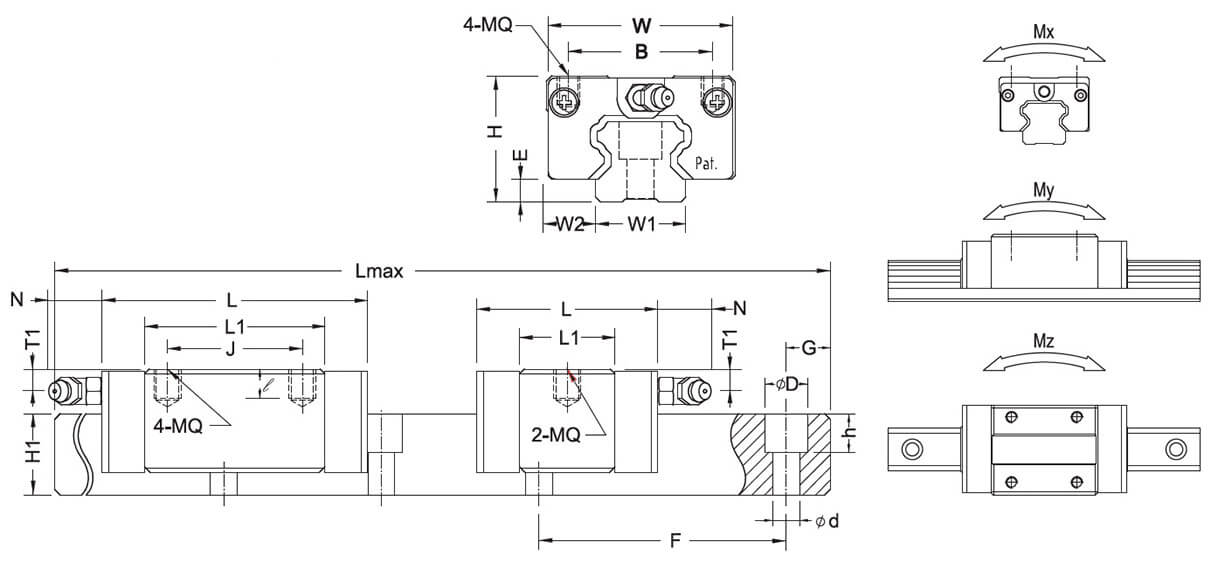

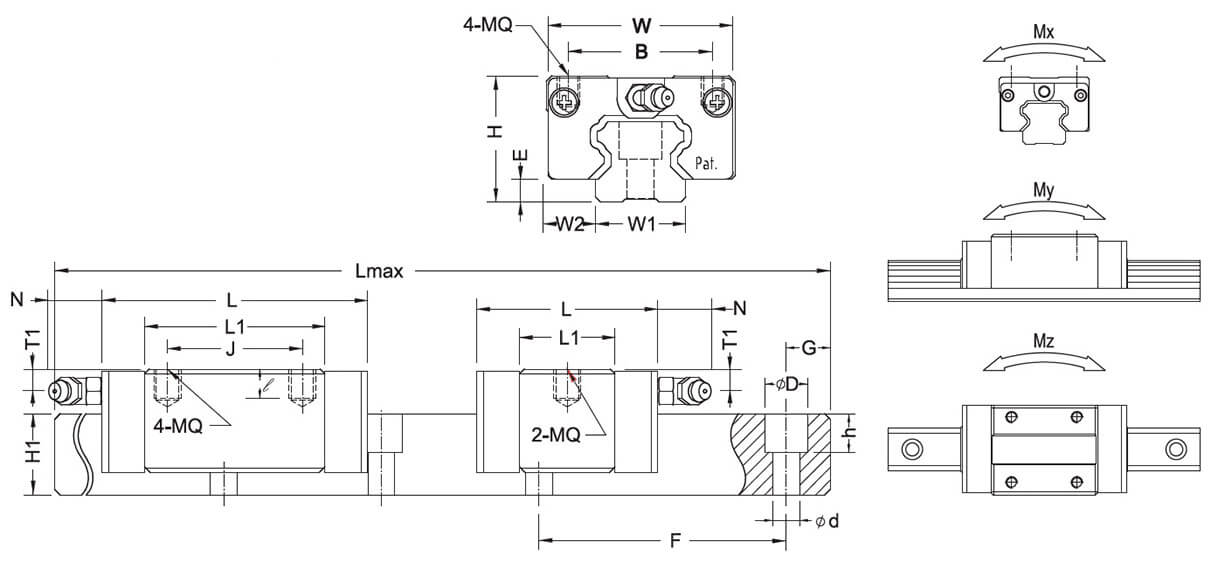

Interchangeability Notice:

- Check the assembly height (H)

- Check the assembly width (W2)

- Check the block length (L)

- Check the block length (L1)

- Check the hole quantity and pitches on the block (B x J)

- Check the rail width (W1)

- Check the pitch of the rail (F)

- Check the hole diameter and rail size (d x D x h)

- Please advise the (G) value in you order

- Check the (E) value to avoid the block grinding the surface of the machine

Product Model : Flanged block, extended length

| Item No. | Assembly | Block | Rail | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | |||||||||||||

| H | W | W2 | E | L | BxJ | MQxℓ | L1 | Oil hole | T1 | (N) | W1 | H1 | F | dxDxh | |

| BRC15A0 | 24 | 47 | 16 | 4.6 | 66 | 38x30 | M5x8 | 40 | Ø3 | 4.3 | 5 | 15 | 14 | 60 | 4.5x7.5x5.8 |

| BRD15A0 | 56 | ||||||||||||||

| BRC20A0 | 30 | 63 | 21.5 | 5 | 77.8 | 53x40 | M6x9 | 48.8 | M6x1 | 7 | 15.6 | 20 | 18 | 60 | 6x9.5x9 |

| BRD20A0 | 67.8 | ||||||||||||||

| BRC20LA | 92.4 | 63.4 | |||||||||||||

| BRD20LA | 82.4 | ||||||||||||||

| BRC25A0 | 36 | 70 | 23.5 | 7 | 88 | 57x45 | M8x12 | 57 | M6x1 | 7.8 | 15.6 | 23 | 22 | 60 | 7x11x9.5 |

| BRD25A0 | 78 | ||||||||||||||

| BRC25LA | 110.1 | 79.1 | |||||||||||||

| BRD25LA | 100.1 | ||||||||||||||

| BRC30A0 | 42 | 90 | 31 | 9 | 109 | 72x52 | M10x12 | 72 | M6x1 | 7 | 15.6 | 28 | 26 | 80 | 9x14x12.5 |

| BRD30A0 | 99 | ||||||||||||||

| BRC30LA | 131.3 | 94.3 | |||||||||||||

| BRD30LA | 121.3 | ||||||||||||||

| BRD35A0 | 48 | 100 | 33 | 9.5 | 109 | 82x62 | M10x13 | 80 | M6x1 | 8 | 15.6 | 34 | 29 | 80 | 9x14x12.5 |

| BRD35LA | 134.8 | 105.8 | |||||||||||||

| BRD45A0 | 60 | 120 | 37.5 | 14 | 138.2 | 100x80 | M12x15 | 105 | M8x1 | 8.5 | 16 | 45 | 38 | 105 | 14x20x17.5 |

| BRD45LA | 163 | 129.8 | |||||||||||||

| Item No. | Dimension(mm) | Basic Load Rating(Kgf) | Static Moment(Kgf*m) | Weight | |||||

|---|---|---|---|---|---|---|---|---|---|

| Lmax | G | C | CO | Mx | My | Mz | Block(Kg) | Rail(Kg/m) | |

| BRC15A0 | 4000 | 20 | 850 | 1350 | 10.1 | 6.8 | 6.8 | 0.21 | 1.4 |

| BRD15A0 | |||||||||

| BRC20A0 | 4000 | 20 | 1400 | 2400 | 24 | 14.6 | 14.6 | 0.4 | 2.6 |

| BRD20A0 | |||||||||

| BRC20LA | 1650 | 3000 | 30 | 23.8 | 23.8 | 0.52 | |||

| BRD20LA | |||||||||

| BRC25A0 | 4000 | 20 | 1950 | 3200 | 36.8 | 22.8 | 22.8 | 0.57 | 3.6 |

| BRD25A0 | |||||||||

| BRC25LA | 2600 | 4600 | 52.9 | 45.5 | 45.5 | 0.72 | |||

| BRD25LA | |||||||||

| BRC30A0 | 4000 | 20 | 2850 | 4800 | 67.2 | 43.2 | 43.2 | 1.1 | 5.2 |

| BRD30A0 | |||||||||

| BRC30LA | 3600 | 6400 | 89.6 | 75.4 | 75.4 | 1.4 | |||

| BRD30LA | |||||||||

| BRD35A0 | 4000 | 20 | 3850 | 6200 | 105.4 | 62 | 62 | 1.6 | 7.2 |

| BRD35LA | 4800 | 8300 | 141.1 | 109.8 | 109.8 | 2 | |||

| BRD45A0 | 4000 | 22.5 | 6500 | 10500 | 236.3 | 137.8 | 137.8 | 2.7 | 12.3 |

| BRD45LA | 7700 | 13000 | 292.5 | 210.9 | 210.9 | 3.6 | |||

.png)

-index.jpg)

_防鬆螺帽-1.jpg)