Bearing lock nuts

Product Introduction

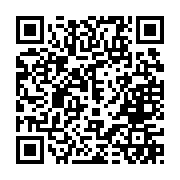

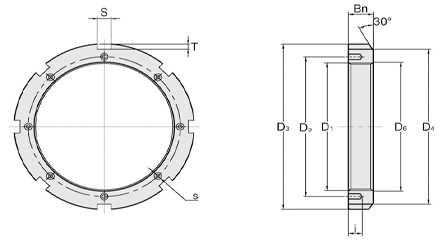

Product Model : AN00-40

01.jpg)

| Lock Nuts No. | D1 Thread | D3 mm | D4 mm | Bn mm | S mm | T mm | D6 mm | Weight kg | Lock Washers No. |

|---|---|---|---|---|---|---|---|---|---|

| AN00 | M10*0.75 | 18 | 13.5 | 4 | 3 | 2 | 10.5 | 0.005 | AW00 |

| AN01 | M12*1.0 | 22 | 17 | 4 | 3 | 2 | 12.5 | 0.007 | AW01 |

| AN02 | M15*1.0 | 25 | 21 | 5 | 4 | 2 | 15.5 | 0.010 | AW02 |

| AN03 | M17*1.0 | 28 | 24 | 5 | 4 | 2 | 17.5 | 0.013 | AW03 |

| AN04 | M20*1.0 | 32 | 26 | 6 | 4 | 2 | 20.5 | 0.019 | AW04 |

| AN05 | M25*1.5 | 38 | 32 | 7 | 5 | 2 | 25.8 | 0.025 | AW05 |

| AN06 | M30*1.5 | 45 | 38 | 7 | 5 | 2 | 30.8 | 0.043 | AW06 |

| AN07 | M35*1.5 | 52 | 44 | 8 | 5 | 2 | 35.8 | 0.053 | AW07 |

| AN08 | M40*1.5 | 58 | 50 | 9 | 6 | 2.5 | 40.8 | 0.085 | AW08 |

| AN09 | M45*1.5 | 65 | 56 | 10 | 6 | 2.5 | 45.8 | 0.119 | AW09 |

| AN10 | M50*1.5 | 70 | 61 | 11 | 6 | 2.5 | 50.8 | 0.148 | AW10 |

| AN11 | M55*2.0 | 75 | 67 | 11 | 7 | 3 | 56 | 0.158 | AW11 |

| AN12 | M60*2.0 | 80 | 73 | 11 | 7 | 3 | 61 | 0.174 | AW12 |

| AN13 | M65*2.0 | 85 | 79 | 12 | 7 | 3 | 66 | 0.203 | AW13 |

| AN14 | M70*2.0 | 92 | 85 | 12 | 8 | 3.5 | 71 | 0.242 | AW14 |

| AN15 | M75*2.0 | 98 | 90 | 13 | 8 | 3.5 | 76 | 0.287 | AW15 |

| AN16 | M80*2.0 | 105 | 95 | 15 | 8 | 3.5 | 81 | 0.397 | AW16 |

| AN17 | M85*2.0 | 110 | 102 | 16 | 8 | 3.5 | 86 | 0.451 | AW17 |

| AN18 | M90*2.0 | 120 | 108 | 16 | 10 | 4 | 91 | 0.556 | AW18 |

| AN19 | M95*2.0 | 125 | 113 | 17 | 10 | 4 | 96 | 0.658 | AW19 |

| AN20 | M100*2.0 | 130 | 120 | 18 | 10 | 4 | 101 | 0.698 | AW20 |

| AN21 | M105*2.0 | 140 | 126 | 18 | 12 | 5 | 106 | 0.845 | AW21 |

| AN22 | M110*2.0 | 145 | 133 | 19 | 12 | 5 | 111 | 0.965 | AW22 |

| AN23 | M115*2.0 | 150 | 137 | 19 | 12 | 5 | 116 | 1.010 | AW23 |

| AN24 | M120*2.0 | 155 | 138 | 20 | 12 | 5 | 121 | 1.080 | AW24 |

| AN25 | M125*2.0 | 160 | 148 | 21 | 12 | 5 | 126 | 1.190 | AW25 |

| AN26 | M130*2.0 | 165 | 149 | 21 | 12 | 5 | 131 | 1.250 | AW26 |

| AN27 | M135*2.0 | 175 | 160 | 22 | 14 | 6 | 136 | 1.550 | AW27 |

| AN28 | M140*2.0 | 180 | 160 | 22 | 14 | 6 | 141 | 1.560 | AW28 |

| AN29 | M145*2.0 | 190 | 171 | 24 | 14 | 6 | 146 | 2.000 | AW29 |

| AN30 | M150*2.0 | 195 | 171 | 24 | 14 | 6 | 151 | 2.030 | AW30 |

| AN31 | M155*3.0 | 200 | 182 | 25 | 16 | 7 | 156.5 | 2.210 | AW31 |

| AN32 | M160*3.0 | 210 | 182 | 25 | 16 | 7 | 161.5 | 2.590 | AW32 |

| AN33 | M165*3.0 | 210 | 193 | 26 | 16 | 7 | 166.5 | 2.430 | AW33 |

| AN34 | M170*3.0 | 220 | 193 | 26 | 16 | 7 | 171.5 | 2.800 | AW34 |

| AN36 | M180*3.0 | 230 | 203 | 27 | 18 | 8 | 181.5 | 3.070 | AW36 |

| AN38 | M190*3.0 | 240 | 214 | 28 | 18 | 8 | 191.5 | 3.390 | AW38 |

| AN40 | M200*3.0 | 250 | 226 | 29 | 18 | 8 | 201.5 | 3.690 | AW40 |

|

|||||||||

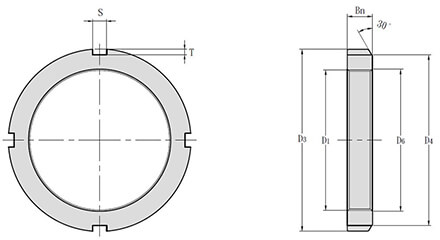

Product Model : KM00-40

| Lock Nuts No. | D1 Thread | D3 mm | D4 mm | Bn mm | S mm | T mm | D6 mm | Weight kg | Lock Washers No. |

|---|---|---|---|---|---|---|---|---|---|

| KM00 | M10*0.75 | 18 | 13.5 | 4 | 3 | 2 | 10.5 | 0.005 | MB00 |

| KM01 | M12*1.0 | 22 | 17 | 4 | 3 | 2 | 12.5 | 0.007 | MB01 |

| KM02 | M15*1.0 | 25 | 21 | 5 | 4 | 2 | 15.5 | 0.010 | MB02 |

| KM03 | M17*1.0 | 28 | 24 | 5 | 4 | 2 | 17.5 | 0.013 | MB03 |

| KM04 | M20*1.0 | 32 | 26 | 6 | 4 | 2 | 20.5 | 0.019 | MB04 |

| KM05 | M25*1.5 | 38 | 32 | 7 | 5 | 2 | 25.8 | 0.025 | MB05 |

| KM06 | M30*1.5 | 45 | 38 | 7 | 5 | 2 | 30.8 | 0.043 | MB06 |

| KM07 | M35*1.5 | 52 | 44 | 8 | 5 | 2 | 35.8 | 0.053 | MB07 |

| KM08 | M40*1.5 | 58 | 50 | 9 | 6 | 2.5 | 40.8 | 0.085 | MB08 |

| KM09 | M45*1.5 | 65 | 56 | 10 | 6 | 2.5 | 45.8 | 0.119 | MB09 |

| KM10 | M50*1.5 | 70 | 61 | 11 | 6 | 2.5 | 50.8 | 0.148 | MB10 |

| KM11 | M55*2.0 | 75 | 67 | 11 | 7 | 3 | 56 | 0.158 | MB11 |

| KM12 | M60*2.0 | 80 | 73 | 11 | 7 | 3 | 61 | 0.174 | MB12 |

| KM13 | M65*2.0 | 85 | 79 | 12 | 7 | 3 | 66 | 0.203 | MB13 |

| KM14 | M70*2.0 | 92 | 85 | 12 | 8 | 3.5 | 71 | 0.242 | MB14 |

| KM15 | M75*2.0 | 98 | 90 | 13 | 8 | 3.5 | 76 | 0.287 | MB15 |

| KM16 | M80*2.0 | 105 | 95 | 15 | 8 | 3.5 | 81 | 0.397 | MB16 |

| KM17 | M85*2.0 | 110 | 102 | 16 | 8 | 3.5 | 86 | 0.451 | MB17 |

| KM18 | M90*2.0 | 120 | 108 | 16 | 10 | 4 | 91 | 0.556 | MB18 |

| KM19 | M95*2.0 | 125 | 113 | 17 | 10 | 4 | 96 | 0.658 | MB19 |

| KM20 | M100*2.0 | 130 | 120 | 18 | 10 | 4 | 101 | 0.698 | MB20 |

| KM21 | M105*2.0 | 140 | 126 | 18 | 12 | 5 | 106 | 0.845 | MB21 |

| KM22 | M110*2.0 | 145 | 133 | 19 | 12 | 5 | 111 | 0.965 | MB22 |

| KM23 | M115*2.0 | 150 | 137 | 19 | 12 | 5 | 116 | 1.010 | MB23 |

| KM24 | M120*2.0 | 155 | 138 | 20 | 12 | 5 | 121 | 1.080 | MB24 |

| KM25 | M125*2.0 | 160 | 148 | 21 | 12 | 5 | 126 | 1.190 | MB25 |

| KM26 | M130*2.0 | 165 | 149 | 21 | 12 | 5 | 131 | 1.250 | MB26 |

| KM27 | M135*2.0 | 175 | 160 | 22 | 14 | 6 | 136 | 1.550 | MB27 |

| KM28 | M140*2.0 | 180 | 160 | 22 | 14 | 6 | 141 | 1.560 | MB28 |

| KM29 | M145*2.0 | 190 | 171 | 24 | 14 | 6 | 146 | 2.000 | MB29 |

| KM30 | M150*2.0 | 195 | 171 | 24 | 14 | 6 | 151 | 2.030 | MB30 |

| KM31 | M155*3.0 | 200 | 182 | 25 | 16 | 7 | 156.5 | 2.210 | MB31 |

| KM32 | M160*3.0 | 210 | 182 | 25 | 16 | 7 | 161.5 | 2.590 | MB32 |

| KM33 | M165*3.0 | 210 | 193 | 26 | 16 | 7 | 166.5 | 2.430 | MB33 |

| KM34 | M170*3.0 | 220 | 193 | 26 | 16 | 7 | 171.5 | 2.800 | MB34 |

| KM36 | M180*3.0 | 230 | 203 | 27 | 18 | 8 | 181.5 | 3.070 | MB36 |

| KM38 | M190*3.0 | 240 | 214 | 28 | 18 | 8 | 191.5 | 3.390 | MB38 |

| KM40 | M200*3.0 | 250 | 226 | 29 | 18 | 8 | 201.5 | 3.690 | MB40 |

|

|||||||||

Product Model : ANL24-40

01.jpg)

| Lock Nuts No. | D1 Thread | D3 mm | D4 mm | Bn mm | S mm | T mm | D6 mm | Weight kg | Lock Washers No. |

|---|---|---|---|---|---|---|---|---|---|

| ANL24 | M120*2.0 | 145 | 135 | 20 | 12 | 5 | 121 | 0.780 | AWL24 |

| ANL26 | M130*2.0 | 155 | 145 | 21 | 12 | 5 | 131 | 0.880 | AWL26 |

| ANL28 | M140*2.0 | 165 | 155 | 22 | 14 | 5 | 141 | 0.990 | AWL28 |

| ANL30 | M150*2.0 | 180 | 170 | 24 | 14 | 5 | 151 | 1.380 | AWL30 |

| ANL32 | M160*3.0 | 190 | 180 | 25 | 16 | 5 | 161.5 | 1.560 | AWL32 |

| ANL34 | M170*3.0 | 200 | 190 | 26 | 16 | 5 | 171.5 | 1.720 | AWL34 |

| ANL36 | M180*3.0 | 210 | 200 | 27 | 18 | 5 | 181.5 | 1.950 | AWL36 |

| ANL38 | M190*3.0 | 220 | 210 | 28 | 18 | 5 | 191.5 | 2.080 | AWL38 |

| ANL40 | M200*3.0 | 240 | 222 | 29 | 18 | 8 | 201.5 | 2.980 | AWL40 |

|

|||||||||

Product Model : KML24-40

| Lock Nuts No. | D1 Thread | D3 mm | D4 mm | Bn mm | S mm | T mm | D6 mm | Weight kg | Lock Washers No. |

|---|---|---|---|---|---|---|---|---|---|

| KML24 | M120*2.0 | 145 | 135 | 20 | 12 | 5 | 121 | 0.78 | MBL24 |

| KML26 | M130*2.0 | 155 | 145 | 21 | 12 | 5 | 131 | 0.88 | MBL26 |

| KML28 | M140*2.0 | 165 | 155 | 22 | 14 | 5 | 141 | 0.99 | MBL28 |

| KML30 | M150*2.0 | 180 | 170 | 24 | 14 | 5 | 151 | 1.38 | MBL30 |

| KML32 | M160*3.0 | 190 | 180 | 25 | 16 | 5 | 161.5 | 1.56 | MBL32 |

| KML34 | M170*3.0 | 200 | 190 | 26 | 16 | 5 | 171.5 | 1.72 | MBL34 |

| KML36 | M180*3.0 | 210 | 200 | 27 | 18 | 5 | 181.5 | 1.95 | MBL36 |

| KML38 | M190*3.0 | 220 | 210 | 28 | 18 | 5 | 191.5 | 2.08 | MBL38 |

| KML40 | M200*3.0 | 240 | 222 | 29 | 18 | 8 | 201.5 | 2.98 | MBL40 |

|

|||||||||

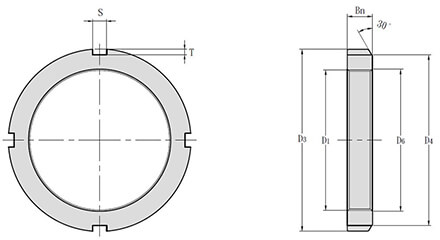

Product Model : AN44-100

02.jpg)

| Lock Nuts No. | D1 Thread1) | D3 mm | D4 mm | S mm | T mm | D6 mm | Bn mm | i mm | Tapped Holes Threads | Dp mm | Suitable Lock Plates No. | Weight kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AN44 | Tr220*4 | 280 | 250 | 20 | 10 | 222 | 32 | 15 | M8*1.25 | 238 | AL44 | 5.200 |

| AN48 | Tr240*4 | 300 | 270 | 20 | 10 | 242 | 34 | 15 | M8*1.25 | 258 | AL48 | 5.950 |

| AN52 | Tr260*4 | 330 | 300 | 24 | 12 | 262 | 36 | 18 | M10*1.5 | 281 | AL52 | 8.050 |

| AN56 | Tr280*4 | 350 | 320 | 24 | 12 | 282 | 38 | 18 | M10*1.5 | 301 | AL56 | 9.050 |

| AN60 | Tr300*4 | 380 | 340 | 24 | 12 | 302 | 40 | 18 | M10*1.5 | 326 | AL60 | 11.800 |

| AN64 | Tr320*5 | 400 | 360 | 24 | 12 | 322.5 | 42 | 18 | M10*1.5 | 345 | AL64 | 13.100 |

| AN68 | Tr340*5 | 440 | 400 | 28 | 15 | 342.5 | 55 | 21 | M12*1.75 | 372 | AL68 | 23.100 |

| AN72 | Tr360*5 | 460 | 420 | 28 | 15 | 362.5 | 58 | 21 | M12*1.75 | 392 | AL72 | 25.100 |

| AN76 | Tr380*5 | 490 | 440 | 32 | 18 | 382.5 | 60 | 21 | M12*1.75 | 414 | AL76 | 30.900 |

| AN80 | Tr400*5 | 520 | 460 | 32 | 18 | 402.5 | 62 | 27 | M16*2 | 439 | AL80 | 36.900 |

| AN84 | Tr420*5 | 540 | 490 | 32 | 18 | 422.5 | 70 | 27 | M16*2 | 459 | AL84 | 43.500 |

| AN88 | Tr440*5 | 560 | 510 | 36 | 20 | 442.5 | 70 | 27 | M16*2 | 477 | AL88 | 45.300 |

| AN92 | Tr460*5 | 580 | 540 | 36 | 20 | 462.5 | 75 | 27 | M16*2 | 497 | AL92 | 50.400 |

| AN96 | Tr480*5 | 620 | 560 | 36 | 20 | 482.5 | 75 | 27 | M16*2 | 527 | AL96 | 62.200 |

| AN100 | Tr500*5 | 630 | 580 | 40 | 23 | 502.5 | 80 | 27 | M16*2 | 539 | AL100 | 63.300 |

|

||||||||||||

Product Model : HM3144-3196

| Lock Nuts NO. | D1 Thread 1) | D3 mm | D4 mm | S mm | T mm | D6 mm | Bn mm | i mm | Tapped Holes Threads | Dp mm | Suitable Lock plates No. | Weight kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HM3144 | Tr220*4 | 280 | 250 | 20 | 10 | 222 | 32 | 15 | M8*1.25 | 238 | AL44 | 5.2 |

| HM3148 | Tr240*4 | 300 | 270 | 20 | 10 | 242 | 34 | 15 | M8*1.25 | 258 | AL48 | 5.95 |

| HM3152 | Tr260*4 | 330 | 300 | 24 | 12 | 262 | 36 | 18 | M10*1.5 | 281 | AL52 | 8.05 |

| HM3156 | Tr280*4 | 350 | 320 | 24 | 12 | 282 | 38 | 18 | M10*1.5 | 301 | AL56 | 9.05 |

| HM3160 | Tr300*4 | 380 | 340 | 24 | 12 | 302 | 40 | 18 | M10*1.5 | 326 | AL60 | 11.8 |

| HM3164 | Tr320*5 | 400 | 360 | 24 | 12 | 322.5 | 42 | 18 | M10*1.5 | 345 | AL64 | 13.1 |

| HM3168 | Tr340*5 | 440 | 400 | 28 | 15 | 342.5 | 55 | 21 | M12*1.75 | 372 | AL68 | 23.1 |

| HM3172 | Tr360*5 | 460 | 420 | 28 | 15 | 362.5 | 58 | 21 | M12*1.75 | 392 | AL72 | 25.1 |

| HM3176 | Tr380*5 | 490 | 440 | 32 | 18 | 382.5 | 60 | 21 | M12*1.75 | 414 | AL76 | 30.9 |

| HM3180 | Tr400*5 | 520 | 460 | 32 | 18 | 402.5 | 62 | 27 | M16*2 | 439 | AL80 | 36.9 |

| HM3184 | Tr420*5 | 540 | 490 | 32 | 18 | 422.5 | 70 | 27 | M16*2 | 459 | AL84 | 43.5 |

| HM3188 | Tr440*5 | 560 | 510 | 36 | 20 | 442.5 | 70 | 27 | M16*2 | 477 | AL88 | 45.3 |

| HM3192 | Tr460*5 | 580 | 540 | 36 | 20 | 462.5 | 75 | 27 | M16*2 | 497 | AL92 | 50.4 |

| HM3196 | Tr480*5 | 620 | 560 | 36 | 20 | 482.5 | 75 | 27 | M16*2 | 527 | AL96 | 62.2 |

|

||||||||||||

Product Model : ANL44-100

02.jpg)

| Lock Nuts No. | D1 Thread1) | D3 mm | D4 mm | S mm | T mm | D6 mm | Bn mm | i mm | Tapped Holes Threads | Dp mm | Suitable Lock Plates No. | Weight kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ANL44 | Tr220*4 | 260 | 242 | 20 | 9 | 222 | 30 | 12 | M6*1 | 229 | ALL44 | 3.090 |

| ANL48 | Tr240*4 | 290 | 270 | 20 | 10 | 242 | 34 | 15 | M8*1.25 | 253 | ALL48 | 5.160 |

| ANL52 | Tr260*4 | 310 | 290 | 20 | 10 | 262 | 34 | 15 | M8*1.25 | 273 | ALL52 | 5.670 |

| ANL56 | Tr280*4 | 330 | 310 | 24 | 10 | 282 | 38 | 15 | M8*1.25 | 293 | ALL56 | 6.780 |

| ANL60 | Tr300*4 | 360 | 336 | 24 | 12 | 302 | 42 | 15 | M8*1.25 | 316 | ALL60 | 9.620 |

| ANL64 | Tr320*5 | 380 | 356 | 24 | 12 | 322.5 | 42 | 15 | M8*1.25 | 335 | ALL64 | 9.940 |

| ANL68 | Tr340*5 | 400 | 376 | 24 | 12 | 342.5 | 45 | 15 | M8*1.25 | 355 | ALL68 | 11.700 |

| ANL72 | Tr360*5 | 420 | 394 | 28 | 13 | 362.5 | 45 | 15 | M8*1.25 | 374 | ALL72 | 12.000 |

| ANL76 | Tr380*5 | 450 | 422 | 28 | 14 | 382.5 | 48 | 18 | M10*1.5 | 398 | ALL76 | 14.900 |

| ANL80 | Tr400*5 | 470 | 442 | 28 | 14 | 402.5 | 52 | 18 | M10*1.5 | 418 | ALL80 | 16.900 |

| ANL84 | Tr420*5 | 490 | 462 | 32 | 14 | 422.5 | 52 | 18 | M10*1.5 | 438 | ALL84 | 17.400 |

| ANL88 | Tr440*5 | 520 | 490 | 32 | 15 | 442.5 | 60 | 21 | M12*1.75 | 462 | ALL88 | 26.200 |

| ANL92 | Tr460*5 | 540 | 510 | 32 | 15 | 462.5 | 60 | 21 | M12*1.75 | 482 | ALL92 | 27.000 |

| ANL96 | Tr480*5 | 560 | 530 | 36 | 15 | 482.5 | 60 | 21 | M12*1.75 | 502 | ALL96 | 28.300 |

| ANL100 | Tr500*5 | 580 | 550 | 36 | 15 | 502.5 | 68 | 21 | M12*1.75 | 522 | ALL100 | 33.600 |

|

||||||||||||

Product Model : HM3044-3096

| Lock Nuts NO. | D1 mm | D3 mm | D4 mm | S mm | T mm | D6 mm | Bn mm | i mm | Tapped Holes Threads | Dp mm | Suitable Lock plates No. | Weight kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HM3044 | Tr220*4 | 260 | 242 | 20 | 9 | 222 | 30 | 12 | M6*1 | 229 | ALL44 | 3.09 |

| HM3048 | Tr240*4 | 290 | 270 | 20 | 10 | 242 | 34 | 15 | M8*1.25 | 253 | ALL48 | 5.16 |

| HM3052 | Tr260*4 | 310 | 290 | 20 | 10 | 262 | 34 | 15 | M8*1.25 | 273 | ALL52 | 5.67 |

| HM3056 | Tr280*4 | 330 | 310 | 24 | 10 | 282 | 38 | 15 | M8*1.25 | 293 | ALL56 | 6.78 |

| HM3060 | Tr300*4 | 360 | 336 | 24 | 12 | 302 | 42 | 15 | M8*1.25 | 316 | ALL60 | 9.62 |

| HM3064 | Tr320*5 | 380 | 356 | 24 | 12 | 322.5 | 42 | 15 | M8*1.25 | 335 | ALL64 | 9.94 |

| HM3068 | Tr340*5 | 400 | 376 | 24 | 12 | 342.5 | 45 | 15 | M8*1.25 | 355 | ALL68 | 11.7 |

| HM3072 | Tr360*5 | 420 | 394 | 28 | 13 | 362.5 | 45 | 15 | M8*1.25 | 374 | ALL72 | 12 |

| HM3076 | Tr380*5 | 450 | 422 | 28 | 14 | 382.5 | 48 | 18 | M10*1.5 | 398 | ALL76 | 14.9 |

| HM3080 | Tr400*5 | 470 | 442 | 28 | 14 | 402.5 | 52 | 18 | M10*1.5 | 418 | ALL80 | 16.9 |

| HM3084 | Tr420*5 | 490 | 462 | 32 | 14 | 422.5 | 52 | 18 | M10*1.5 | 438 | ALL84 | 17.4 |

| HM3088 | Tr440*5 | 520 | 490 | 32 | 15 | 442.5 | 60 | 21 | M12*1.75 | 462 | ALL88 | 26.2 |

| HM3092 | Tr460*5 | 540 | 510 | 32 | 15 | 462.5 | 60 | 21 | M12*1.75 | 482 | ALL92 | 29.6 |

| HM3096 | Tr480*5 | 560 | 530 | 36 | 15 | 482.5 | 60 | 21 | M12*1.75 | 502 | ALL96 | 28.3 |

|

||||||||||||

Product Model : HM HN

01.jpg)

| Lock Nuts No. | D1 Thread1) | D3 mm | D4 mm | Bn mm | S mm | T mm | D6 mm | Weight kg |

|---|---|---|---|---|---|---|---|---|

| HM42 | Tr210*4 | 270 | 238 | 30 | 20 | 10 | 212 | 4.750 |

| HM44 | Tr220*4 | 280 | 250 | 32 | 20 | 10 | 222 | 5.350 |

| HM46 | Tr230*4 | 290 | 260 | 34 | 20 | 10 | 232 | 5.800 |

| HM48 | Tr240*4 | 300 | 270 | 34 | 20 | 10 | 242 | 6.200 |

| HM50 | Tr250*4 | 320 | 290 | 36 | 20 | 10 | 252 | 7.000 |

| HM52 | Tr260*4 | 330 | 300 | 36 | 24 | 12 | 262 | 8.550 |

| HM54 | Tr270*4 | 340 | 310 | 38 | 24 | 12 | 272 | 9.200 |

| HM56 | Tr280*4 | 350 | 320 | 38 | 24 | 12 | 282 | 10.000 |

| HM58 | Tr290*4 | 370 | 330 | 40 | 24 | 12 | 292 | 11.800 |

| HM60 | Tr300*4 | 380 | 340 | 40 | 24 | 12 | 302 | 12.000 |

| HM62 | Tr310*5 | 390 | 350 | 42 | 24 | 12 | 312.5 | 13.400 |

| HM64 | Tr320*5 | 400 | 360 | 42 | 24 | 12 | 322.5 | 13.500 |

| HM66 | Tr330*5 | 420 | 380 | 52 | 28 | 15 | 332.5 | 20.400 |

| HM68 | Tr340*5 | 440 | 400 | 55 | 28 | 15 | 342.5 | 24.500 |

| HM70 | Tr350*5 | 450 | 410 | 55 | 28 | 15 | 352.5 | 25.200 |

| HM72 | Tr360*5 | 460 | 420 | 58 | 28 | 15 | 362.5 | 27.500 |

| HM74 | Tr370*5 | 470 | 430 | 58 | 28 | 15 | 372.5 | 28.200 |

| HM76 | Tr380*5 | 490 | 440 | 60 | 32 | 18 | 382.5 | 33.500 |

| HM80 | Tr400*5 | 520 | 460 | 62 | 32 | 18 | 402.5 | 40.000 |

| HM84 | Tr420*5 | 540 | 490 | 70 | 32 | 18 | 422.5 | 46.900 |

| HM88 | Tr440*5 | 560 | 510 | 70 | 36 | 20 | 442.5 | 48.500 |

| HM92 | Tr460*5 | 580 | 540 | 75 | 36 | 20 | 462.5 | 55.000 |

| HM96 | Tr480*5 | 620 | 560 | 75 | 36 | 20 | 482.5 | 67.000 |

| HM100 | Tr500*5 | 630 | 590 | 80 | 40 | 23 | 502.5 | 69.000 |

| HM102 | Tr510*6 | 650 | 590 | 80 | 40 | 23 | 513 | 75.000 |

| HM106 | Tr530*6 | 670 | 610 | 80 | 40 | 23 | 533 | 78.000 |

| HM110 | Tr550*6 | 700 | 640 | 80 | 40 | 23 | 553 | 92.500 |

|

||||||||

Product Model : HML HNL

01.jpg)

| Lock Nuts No. | D1 Thread1) | D3 mm | D4 mm | Bn mm | S mm | T mm | D6 mm | Weight kg |

|---|---|---|---|---|---|---|---|---|

| HML41 | Tr205*4 | 250 | 232 | 30 | 18 | 8 | 207 | 3.430 |

| HML43 | Tr215*4 | 260 | 242 | 30 | 20 | 9 | 217 | 3.720 |

| HML47 | Tr235*4 | 280 | 262 | 34 | 20 | 9 | 237 | 4.600 |

| HML52 | Tr260*4 | 310 | 290 | 34 | 20 | 10 | 262 | 5.800 |

| HML56 | Tr280*4 | 330 | 310 | 38 | 24 | 10 | 282 | 6.720 |

| HML60 | Tr300*4 | 360 | 336 | 42 | 24 | 12 | 302 | 9.600 |

| HML64 | Tr320*5 | 380 | 356 | 42 | 24 | 12 | 322.5 | 10.300 |

| HML69 | Tr345*5 | 410 | 384 | 45 | 28 | 13 | 347.5 | 11.500 |

| HML72 | Tr360*5 | 420 | 394 | 45 | 28 | 13 | 362.5 | 12.100 |

| HML73 | Tr365*5 | 430 | 404 | 48 | 28 | 13 | 367.5 | 14.200 |

| HML76 | Tr380*5 | 450 | 422 | 48 | 28 | 14 | 382.5 | 16.000 |

| HML77 | Tr385*5 | 450 | 422 | 48 | 28 | 14 | 387.5 | 15.000 |

| HML80 | Tr400*5 | 470 | 442 | 52 | 28 | 14 | 402.5 | 18.500 |

| HML82 | Tr410*5 | 480 | 452 | 52 | 32 | 14 | 412.5 | 19.000 |

| HML84 | Tr420*5 | 490 | 462 | 52 | 32 | 14 | 422.5 | 19.400 |

| HML86 | Tr430*5 | 500 | 472 | 52 | 32 | 14 | 432.5 | 19.800 |

| HML88 | Tr440*5 | 520 | 490 | 60 | 32 | 15 | 442.5 | 27.000 |

| HML90 | Tr450*5 | 520 | 490 | 60 | 32 | 15 | 452.5 | 27.500 |

| HML92 | Tr460*5 | 540 | 510 | 60 | 32 | 15 | 462.5 | 28.000 |

| HML94 | Tr470*5 | 540 | 510 | 60 | 32 | 15 | 472.5 | 28.500 |

| HML96 | Tr480*5 | 560 | 530 | 60 | 36 | 15 | 482.5 | 29.500 |

| HML98 | Tr490*5 | 580 | 550 | 60 | 36 | 15 | 492.5 | 34.000 |

| HML100 | Tr500*5 | 580 | 550 | 68 | 36 | 15 | 502.5 | 35.000 |

| HML104 | Tr520*6 | 600 | 570 | 68 | 36 | 15 | 523 | 37.000 |

| HML106 | Tr530*6 | 630 | 590 | 68 | 40 | 20 | 533 | 47.000 |

| HML108 | Tr540*6 | 630 | 590 | 68 | 40 | 20 | 543 | 43.500 |

|

||||||||

.png)

-index.jpg)

_防鬆螺帽-1.jpg)