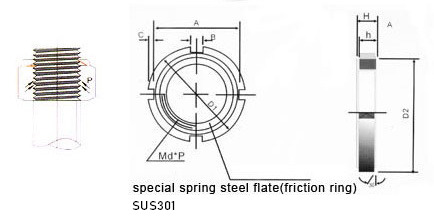

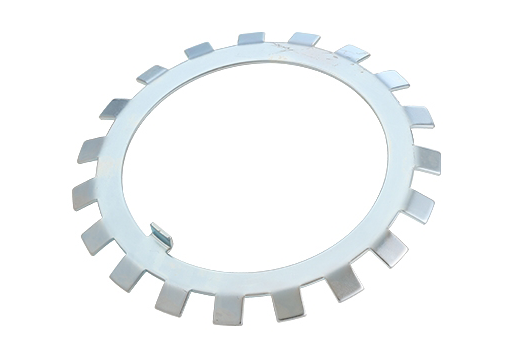

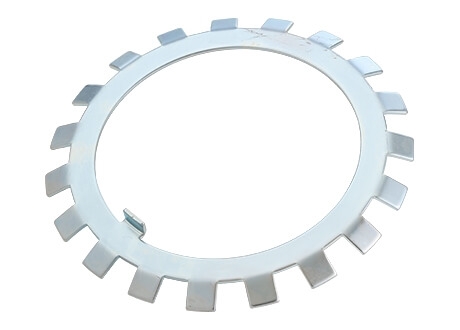

Prevailing Torque Bearing Nut With Metal Insert/Bearing Lock Nuts

Product Introduction

Product Model : Prevailing Torque Bearing Nut With Metal Insert

Material option:

SAE1008 Low Carbon Steel

C1045 Medium Carbon Steel

SUS304 Stainless Steel

| No. | Thread(d*p) | D1 | D2 | A | C | B | h | H | Kg | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AN00 | M 10*0.75 | 18 | 0-0.2 | 13 | 0+0.2 | 14 (14.4) |

0-0.2 | 2 (1.8) |

3 | +0.1 | 4 | 5.2 | +0.3 | 0.007 |

| AN01 | M 12*1 | 22 | 0-0.2 | 17 | 0+0.2 | 18 (18.4) |

0-0.2 | 2 (1.8) |

3 | +0.1 | 4 | 5.4 | +0.3 | 0.0075 |

| AN02 | M 15*1 | 25 | 0-0.5 | 21 | 0-0.5 | 21 (21.4) |

0-0.5 | 2 (1.8) |

4 | +0.2 | 5 | 6.5 | +0.5 | 0.010 |

| AN03 | M 17*1 | 28 | 0-0.5 | 24 | 0-0.5 | 24 (24.2) |

0-0.5 | 2 (1.9) |

4 | +0.2 | 5 | 6.4 | +0.5 | 0.014 |

| AN04 | M 20*1 | 32 | 0-0.5 | 26 | 0-0.5 | 28 (28.4) |

0-0.5 | 2 (1.8) |

4 | +0.2 | 6 | 7.7 | +0.5 | 0.022 |

| AN05 | M 25*1.5 | 38 | 0-0.5 | 32 | 0-0.5 | 34 | 0-0.5 | 2 | 5 | +0.2 | 7 | 9.1 | +0.5 | 0.035 |

| AN06 | M 30*1.5 | 45 | 0-0.5 | 38 | 0-0.5 | 41 | 0-0.5 | 2 | 5 | +0.2 | 7 | 9.1 | +0.8 | 0.048 |

| AN07 | M35*1.5 | 52 | 0-0.5 | 44 | 0-0.5 | 48 | 0-0.5 | 2 | 5 | +0.2 | 8 | 10.2 | +0.8 | 0.075 |

| AN08 | M 40*1.5 | 58 | 0-0.5 | 50 | 0-0.5 | 53 | 0-0.5 | 2.5 | 6 | +0.2 | 9 | 11.2 | +0.8 | 0.098 |

| AN09 | M 45*1.5 | 65 | 0-0.5 | 56 | 0-0.5 | 60 | 0-0.5 | 2.5 | 6 | +0.2 | 10 | 12.5 | +1.0 | 0.14 |

| AN10 | M 50*1.5 | 70 | 0-0.5 | 61 | 0-0.5 | 65 | 0-0.5 | 2.5 | 6 | +0.2 | 11 | 13.5 | +1.0 | 0.167 |

| AN11 | M 55*2 | 75 | 0-0.5 | 67 | 0-0.5 | 69 | 0-0.5 | 3 | 7 | +0.2 | 11 | 13.5 | +1.0 | 0.17 |

| AN12 | M 60*2 | 80 | 0-0.5 | 73 | 0-0.5 | 74 | 0-0.5 | 3 | 7 | +0.2 | 11 | 13.5 | +1.0 | 0.195 |

| AN13 | M 65*2 | 85 | 0-0.5 | 79 | 0-0.5 | 79 | 0-0.5 | 3 | 7 | +0.2 | 12 | 15 | +1.5 | 0.224 |

| AN14 | M 70*2 | 92 | 0-0.5 | 85 | 0-0.5 | 85 | 0-0.5 | 3.5 | 8 | +0.2 | 12 | 15 | +1.5 | 0.292 |

| AN15 | M 75*2 | 98 | 0-0.5 | 90 | 0-0.5 | 91 | 0-0.5 | 3.5 | 8 | +0.2 | 13 | 15.8 | +1.5 | 0.33 |

| AN16 | M 80*2 | 105 | 0-0.5 | 95 | 0-0.5 | 98 | 0-0.5 | 3.5 | 8 | +0.2 | 15 | 18.6 | +1.5 | 0.42 |

| AN17 | M 85*2 | 110 | 0-0.5 | 102 | 0-0.75 | 103 | 0-0.5 | 3.5 | 8 | +0.2 | 16 | 19.2 | +1.5 | 0.505 |

| AN18 | M 90*2 | 120 | 0-0.5 | 108 | 0 -0.75 | 112 | 0-0.5 | 4 | 10 | +0.3 | 16 | 20.3 | +1.5 | 0.69 |

| AN19 | M 95*2 | 125 | 0-0.5 | 113 | 0 -0.75 | 117 | 0-0.5 | 4 | 10 | +0.3 | 17 | 21.3 | +1.5 | 0.755 |

| AN20 | M 100*2 | 130 | 0-0.5 | 120 | 0 -0.75 | 122 | 0-0.5 | 4 | 10 | +0.3 | 18 | 22.3 | +1.5 | 0.855 |

|

||||||||||||||

.png)

-index.jpg)

_防鬆螺帽-1.jpg)